A-dec Control Platform

Helping an industry leader create an experience platform that enables faster and more diverse product launches.

EASY TO LEARN AND EASY TO USE - DYNAMICALLY SIMPLE

Together with A-dec leadership, industrial design, engineering, and software development teams, Fine Counsel concepted, planned, and designed a control platform for the future of A-dec dental equipment.

“THAT IS AN EXPENSIVE 15 YEAR OLD CHAIR.”

For years, A-dec has made highly regarded and reliable products. However, its flagship product line had not been updated in 15 years. It continues to sell well but is increasingly referred to as just an expensive “chair”.

FIRST, WE NEEDED TO INCREASE THE PACE OF PRODUCT UPDATES

We started with new hardware designed by the A-dec industrial design team. We wanted to take our time getting the software right so we used the existing software and redesigned the housing and controls with a capacitive glass surface that replaced older mechanical domed switches. This meant less cracking and peeling and better use and cleaning. The updated physical hardware would allow us to add the new software platform when we were ready.

We then focused on what we would making now and into the future

RESEARCHING needed FUNCTIONALITY in OUR NEW SOFTWARE

We conducted quantitative and qualitative discovery research in the United States and Europe to identify significant use scenarios, relevant context and meaningful functionality.

EVALUATING OUR CONCEPTS AND VALIDATING OUR WORK

Through several iterations we consulted with our customers about the choices we were making. Did we translate their needs appropriately into use? Was it as easy to learn and simple to use as we thought? This back-and-forth involvement by the dealer networks, practice owners, and the actual doctors meant that we could trust what we were making.

WE REBUILT THE ARCHITECTURE TO SUPPORT A SOFTWARE PLATFORM WE REFER TO AS “CENTER OF CONTROL”

We used a full touch screen to give complete UI flexibility - any control could be added or taken away from the screen. We split the electrical and software architecture into two parts. One would be subject to 510k pre-market submission and could take the time needed for regulatory approval. The other part would be non-510k so the new product launch cycles could move much faster.

OUR VISUAL LANGUAGE WAS SIMPLE, PROFESSIONAL, AND FLEXIBLE

By creating modular instrument components we could release an SDK and API’s for our partners to integrate their existing and future products. This functionality could be released as connected, downloadable upgrades at any time by customers. Additionally, that same software could adapt to the multiple screens needed to communicate within the treatment room.

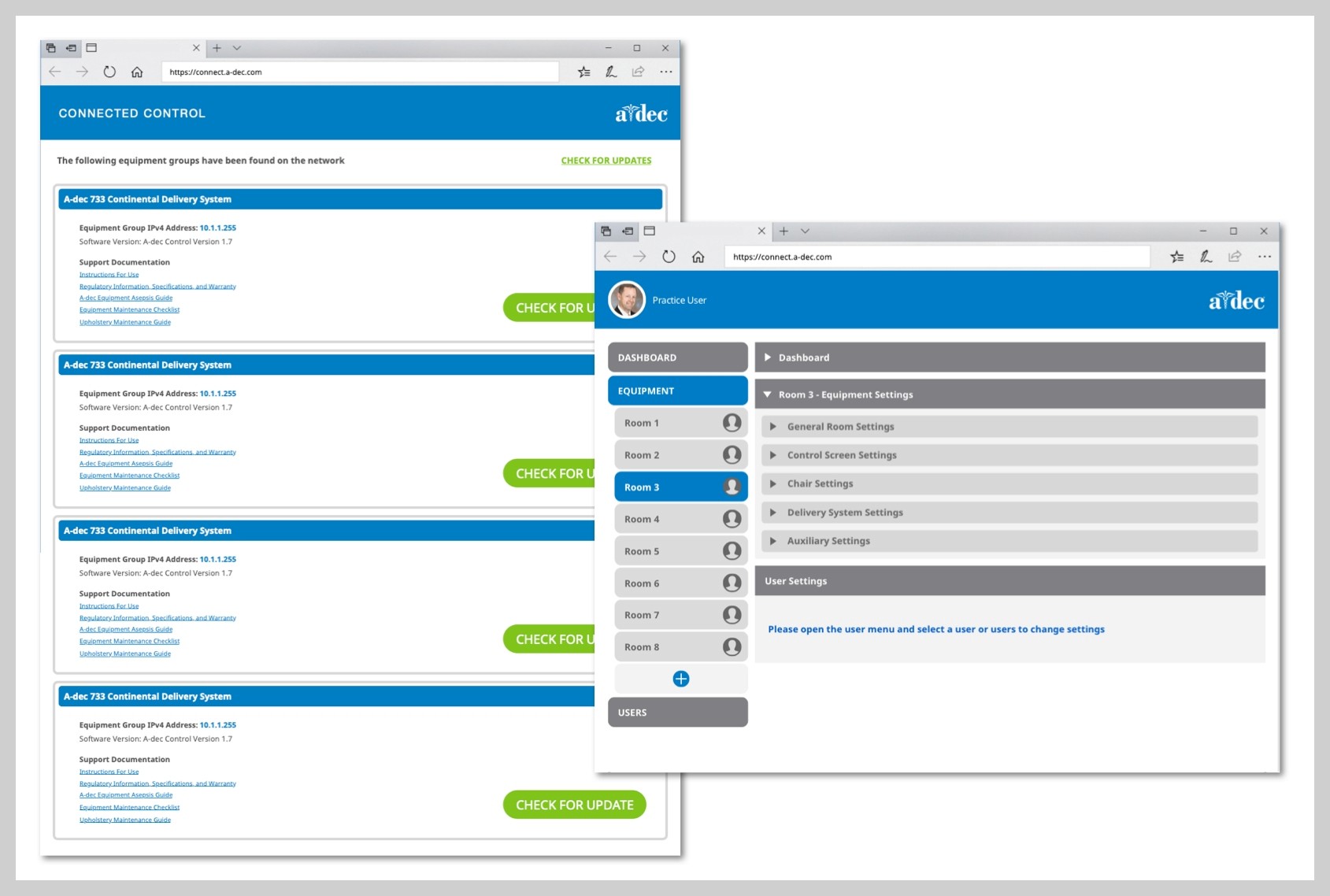

CONNECTED DEVICES MANAGED REMOTELY FOR LARGE DENTAL SERVICE ORGANIZATIONS

Setup, monitoring and management of multiple equipment groups, rooms, and users is augmented by data collection services built into the hardware and software. This also allows for service technicians to more easily identify problems and fix equipment.

OPENING THE DOOR FOR FUTURE VR/XR CONTROL INNOVATION

By creating a modular and connected control software platform we can explore how the content and control functionality can be more finely tuned for each unique user context. Whether it’s the chair-side needs of the doctor or hygienist or even entertainment and comfort functions for the patient. This includes office communication features as well as changing out glass control screens for wearable XR interfaces in the future.